Large metal cutting is an essential aspect of virtually any metal fabrication project. With this in mind, the capabilities in our facility have been strategically acquired and positioned to offer every part, component, assembly, or fabrication the type of cutting that delivers the quality and precision you need. From sawing, shearing and punching to state-of-the-art laser cutting and plasma cutting, comprehensive cutting capabilities help make GMF a true one-stop fabrication solution.

Versatility

When it comes to cutting material for your fabrications - whether it’s sheet metal or bar-stock, the cutting process used is always guided by a number of factors ranging from the material used and the intended application, to specific cutting scenarios related to your fabrication’s design. For this purpose, our variety of cutting technologies provides an option for virtually any task.

Technology

From the tried and true results of shearing and sawing to state-of-the art laser and plasma cutting – the cutting technology available under our roof empowers our technicians to deliver the quality and precision every customer needs – no matter how complex the specification.

Speed and Efficiency

From simple to complex, all of our large metal cutting machines are designed to minimize scrap and conform to our lean manufacturing practices. High tech cutting machinery helps shorten lead times and reduce the need for additional tooling.

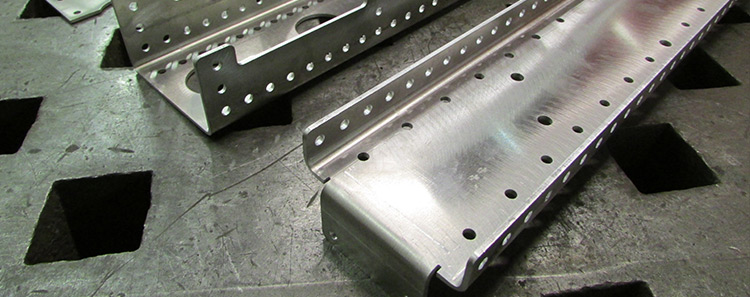

Shearing - Laser Cutting - Plasma Cutting

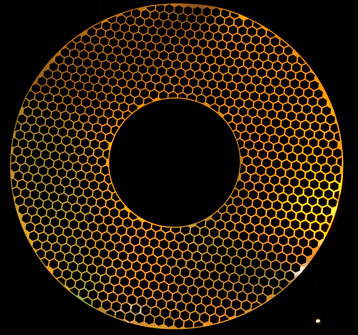

The advanced capabilities of laser cutting come with a variety of advantages for fabrications required by a wide range of customers. Chief among these is efficiency. In addition to using less energy and being more precise than other methods, laser cutting also reduces the need for some additional machining processes. On top of this, a reduction of workpiece contamination also makes the process attractive for a number of industries. If you need good edge quality, small diameter holes, or complex details – laser cutting is a great option. At GMFCO, we frequently recommend laser cutting for parts and fabrications that require very tight tolerances.

Automated high definition plasma cutting is an accurate and versatile option for a number of projects. For thicker materials, plasma cutting can achieve a greater speed than laser cutting, without sacrificing quality. This makes it ideal for large metal cutting and fabrication jobs. In addition to this, the slight bevel produced by plasma cutting is an ideal companion for the sturdier welds required by large fabrications. If parts don’t require complex cuts or small diameter holes, plasma cutting is efficient, fast, and powerful.

Large metal shearing is a fast and efficient method for cutting large metal sheets into precise shapes and sizes. At GMFCO, our advanced shearing capabilities, including the LVD Square Shear and Gaur Safety Edger, allow us to handle a wide range of materials and thicknesses. Whether working with steel, stainless steel, or aluminum, our shearing processes deliver clean, accurate cuts with minimal waste.

LVD Square Shear: Handles 1/2" thick steel, 3/8" stainless steel, and 3/4" aluminum, accommodating lengths up to 16'6".

Gaur Safety Edger: Processes strips 1/16” to 1/4” thick and up to 10” wide, de-twisting, straightening, and adding a smooth radius to corners.

Our shearing services are ideal for creating consistent, high-quality parts efficiently, reducing lead times while maintaining strict tolerances.